From Regulatory Chaos to AI-Powered Clarity: A Manufacturing Intelligence Revolution

How we transformed the nightmare of manufacturing compliance into an intelligent, automated system—and where AI is taking us next

🎯 The Million-Dollar Problem Nobody Talks About

Picture this: You're launching a new electronic device across 50 countries. Each country has different regulations about what materials can be used, how much of each substance is allowed, and what happens to the product at end-of-life. Your suppliers send you composition data in hundreds of different formats—some in broken English, others using proprietary chemical names, and many missing critical information entirely.

This is the hidden crisis facing every global manufacturer today. Behind every smartphone, laptop, and IoT device lies a complex web of materials compliance that can make or break a product launch. Get it wrong, and you're facing recalls, fines, and banned products. Get it right manually, and you're drowning in spreadsheets and prayer.

The beneficiaries of our solution span the entire manufacturing ecosystem:

Global manufacturers who need consistent, reliable compliance data across their supply chains

Supply chain managers who can finally trust their Bill of Materials (BOM) data

Environmental teams working on sustainability and recycling programs

Regulatory affairs professionals who no longer lose sleep over compliance audits

Consumers who get safer, more sustainable products as a result

Our invention, now protected under US Patent 12,339,890 B2, solved this problem by creating the first automated system for classifying manufacturing parts based on their actual material composition—not what suppliers claim they contain.

🧩 Breaking Down the Impossible: Our Three-Layer Strategy

When we first tackled this challenge, the problem seemed impossibly complex. How do you teach a machine to understand that "Al 6061-T6" and "Aluminum alloy, precipitation-hardened" refer to the same material? How do you handle suppliers who describe plastic as "黑色塑料" or "matière plastique noire"?

We realized that no single approach could solve this puzzle. Instead, we needed to build a sophisticated classification pipeline that combines multiple techniques, each handling different aspects of the problem.

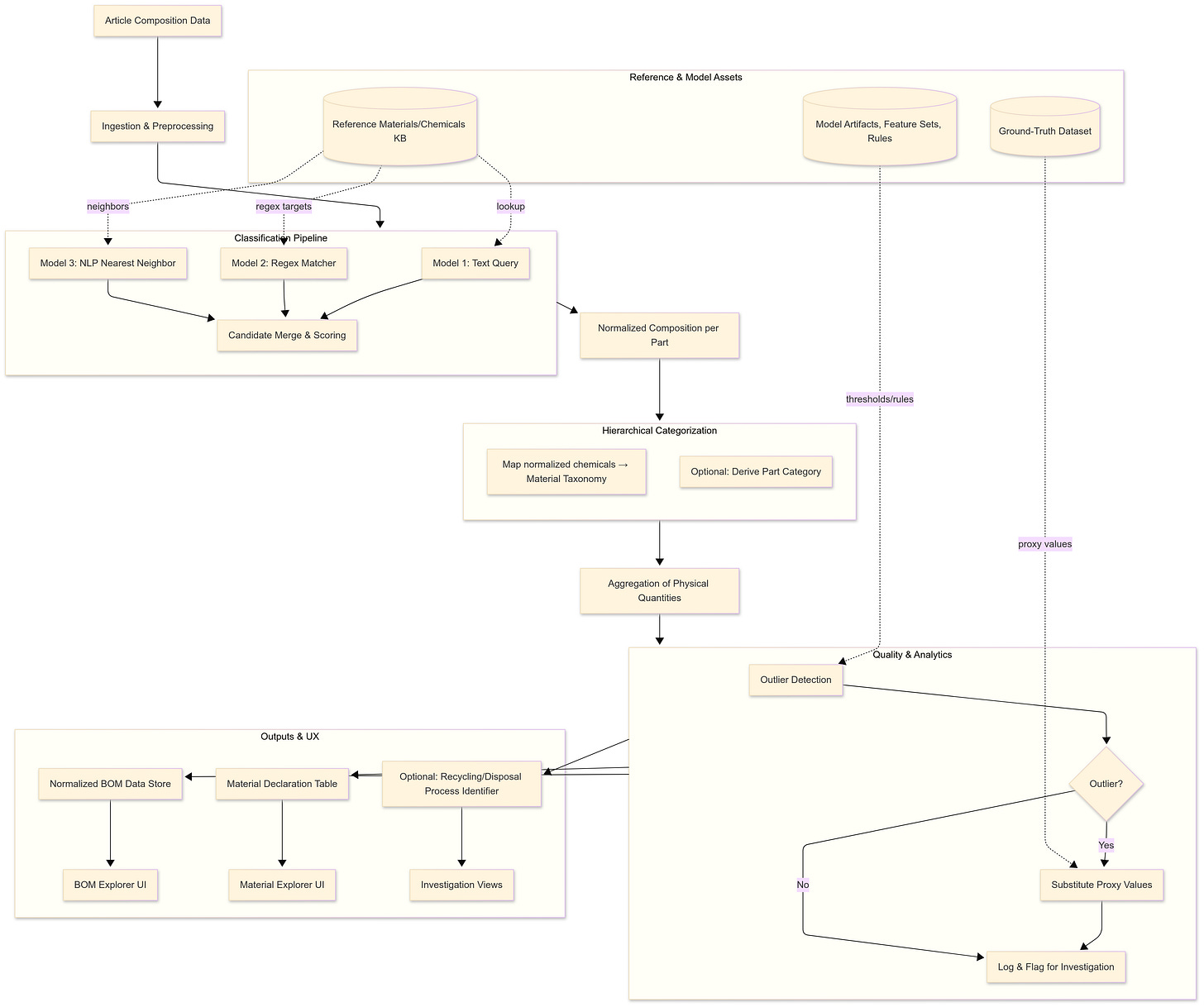

The High-Level Architecture

Our breakthrough was realizing that material classification isn't just a data problem—it's a multi-layered intelligence problem. We needed to combine:

Domain expertise captured in chemical rules and taxonomies

Pattern recognition for catching common naming conventions

Semantic understanding for handling language variations and synonyms

Quality assurance to catch and correct outliers automatically

The Three-Model Ensemble

Rather than building one complex AI system, we created three specialized "experts" that work together:

Expert 1: The Librarian (Text Query Model)

This model treats our curated knowledge base like a massive digital library. When it sees "stainless steel 316L," it instantly searches through thousands of known materials and finds exact or near-exact matches. It's incredibly fast and accurate for well-documented materials.

Expert 2: The Pattern Detective (Regex Matcher)

Some materials follow predictable naming patterns—aluminum alloys often start with "Al", polymers might include "PE" or "PP". This expert learned thousands of industry-standard patterns and can classify materials even when they're abbreviated or encoded.

Expert 3: The Language Translator (NLP Nearest Neighbor)

This is our most sophisticated expert. Using natural language processing, it understands that "acier inoxydable" (French) and "stainless steel" (English) refer to the same material family. It can handle typos, alternative spellings, and even creative supplier descriptions.

⚡ The Technical Arsenal: Skills That Made It Possible

Building this system required pulling together expertise from multiple domains. Here's the technical DNA of our solution:

Machine Learning & AI Techniques

K-Nearest Neighbor (KNN) Classification for handling semantic similarity between material descriptions

Multi-variate Outlier Detection using Bayesian methods to identify suspicious composition data

Ensemble Methods combining three different classification approaches for robust results

Feature Engineering to extract meaningful signals from messy supplier data

Chemical Informatics

PubChem Integration leveraging the world's largest chemical database for standardized identifiers

Chemical Rule Books encoding decades of materials science knowledge into machine-readable formats

Taxonomy Mapping organizing the chaos of material names into structured hierarchies

Normalization Processes (N1-N4) for handling complex polymer classifications

Data Engineering & Processing

Multi-format Ingestion handling everything from Excel spreadsheets to XML feeds

Data Quality Pipelines with automated cleansing, validation, and transformation

Provenance Tracking maintaining complete audit trails for regulatory compliance

Proxy Generation automatically substituting reliable values when supplier data is questionable

System Architecture Patterns

Pipeline Architecture enabling scalable processing of massive BOMs

Reference Knowledge Base serving as the single source of truth for material classifications

Human-in-the-Loop Design preserving expert oversight while automating routine decisions

Hierarchical Classification from individual chemicals up to complete assemblies

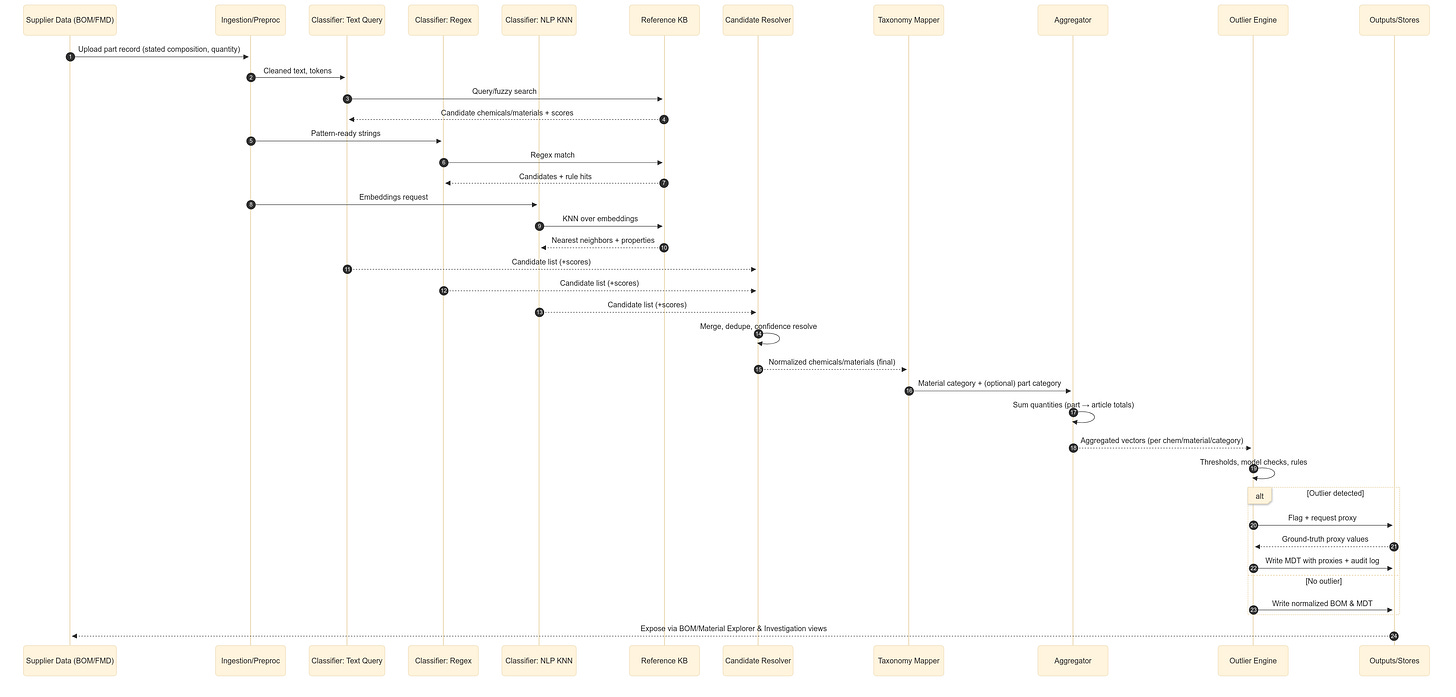

The Part-Level Classification Dance

Here's how all these pieces work together when a new part enters our system:

What makes this sequence powerful is that it's deterministic and auditable. Every decision has a clear rationale, and humans can always understand and override the system's choices. This isn't a black box—it's an intelligent assistant that shows its work.

🚀 The AI Evolution: Where We're Headed Next

Having solved the core classification problem, we're now embarking on the next phase of our journey: transforming our robust, rule-based system into an intelligent AI agent that doesn't just classify materials—it converses with users, explains its reasoning, and actively helps solve supply chain challenges.

From Data Processor to AI Copilot

Our next-generation system, outlined in our AI-first roadmap, represents a fundamental shift in how humans interact with manufacturing intelligence. Instead of navigating complex dashboards and running pre-built reports, users will simply ask questions in natural language and get intelligent, contextual responses.

Here's what the future looks like:

Capability 1: The Explainer Agent

"Why did you classify this part as containing hazardous materials?"

Instead of cryptic classification codes, our AI agent will provide clear, conversational explanations: "I classified this part as hazardous because it contains 0.15% lead, which exceeds the 0.1% threshold under RoHS regulations. This determination is based on the supplier's declaration from Supplier X, cross-referenced with our chemical knowledge base entry CAS-7439-92-1, last updated in regulatory pack v4.2."

Capability 2: The Query Translator

"Show me all articles with more than 0.1% cobalt by mass that we shipped to Europe last quarter"

Our natural language query system will translate business questions directly into precise database queries, complete with safety guardrails and transparency. Users see both the generated SQL and the results, maintaining trust and control while dramatically reducing time-to-insight.

Capability 3: The Supplier Communications Assistant

"Draft an email asking Supplier Y to clarify the missing composition data for Part ABC-123"

When the system flags incomplete or suspicious supplier data, our AI agent will generate structured, professional requests for clarification. It knows what information is missing, what format is required, and how to ask in a way that gets results. When suppliers respond, the agent will summarize the key information and propose normalized data entries for human review.

Capability 4: The Regulatory Change Interpreter

"Explain how the new RoHS update affects our product line"

Regulatory changes are complex and frequent. Our AI agent will analyze regulatory updates, compare them against current product compositions, and generate plain-English summaries of what's changed, which products are affected, and what actions need to be taken.

The Architecture Evolution

Our AI-first architecture builds intelligently on our existing foundation:

Core Principle: AI Enhances, Never Replaces

The deterministic classification pipeline remains our foundation. AI adds a conversational layer that makes the system more accessible and actionable, but never bypasses our proven governance and audit controls.

New Components:

GenAI Service: Stateless Azure-hosted service that provides natural language capabilities via function calling to our existing tools

RAG (Retrieval-Augmented Generation) Index: Smart search across our knowledge base, regulatory documents, and historical decisions

Prompt Library: Versioned, tested prompts for each AI capability, ensuring consistent and reliable responses

Safety Guardrails: Multiple layers of protection to prevent hallucination and ensure all AI outputs are grounded in our authoritative data

Why This Matters for Manufacturing

This evolution represents more than just a technology upgrade—it's a fundamental reimagining of how humans and machines collaborate in manufacturing intelligence:

Democratization of Expertise: Complex materials science knowledge becomes accessible to supply chain managers, procurement specialists, and quality engineers without deep technical backgrounds.

Proactive Problem Solving: Instead of reactive compliance checking, the system becomes a proactive partner that identifies issues, suggests solutions, and helps prevent problems before they occur.

Continuous Learning: The AI layer learns from every interaction, every expert decision, and every regulatory change, constantly improving its ability to serve the manufacturing community.

Human-AI Partnership: Rather than replacing human expertise, our AI agent amplifies it—handling routine questions instantly while escalating complex decisions to human experts with full context and recommendations.

🌟 The Bigger Picture: Manufacturing Intelligence Revolution

What started as a solution to a specific compliance headache has evolved into something much larger: a blueprint for how AI can transform manufacturing intelligence. Our patent represents not just a technical achievement, but a new paradigm for human-machine collaboration in industrial settings.

The manufacturing industry is at an inflection point. Supply chains are increasingly complex, regulations are multiplying, and sustainability requirements are becoming non-negotiable. The old approaches of manual data management and reactive compliance checking simply cannot scale to meet these challenges.

Our solution proves that with the right combination of domain expertise, machine learning, and thoughtful AI integration, we can create systems that are both incredibly sophisticated and remarkably easy to use. Systems that make expert knowledge accessible to everyone who needs it, when they need it.

This is just the beginning. As we continue to evolve our platform from a classification engine to a comprehensive AI agent, we're not just solving today's problems—we're building the foundation for the next generation of intelligent manufacturing systems.

The future of manufacturing isn't just automated—it's intelligently automated, with AI agents that understand context, explain their reasoning, and continuously learn from human expertise. Our patent and our roadmap represent a significant step toward that future.

Ready to dive deeper into the technical details? The complete patent documentation and our AI-first development roadmap are available for technical audiences interested in the implementation specifics. Whether you're building similar systems, researching manufacturing AI, or exploring regulatory compliance automation, we'd love to connect and share insights.

About the Innovation

US Patent 12,339,890 B2: "Part Composition Classification for Articles of Manufacture" was granted to Microsoft Technology Licensing, LLC on June 24, 2025. The invention represents a breakthrough in automated materials compliance and supply chain intelligence, with applications across electronics, automotive, aerospace, and consumer goods manufacturing.

Inventors - Clarence Wong, Durgesh Nandini Das, Srikanth Ranganathan